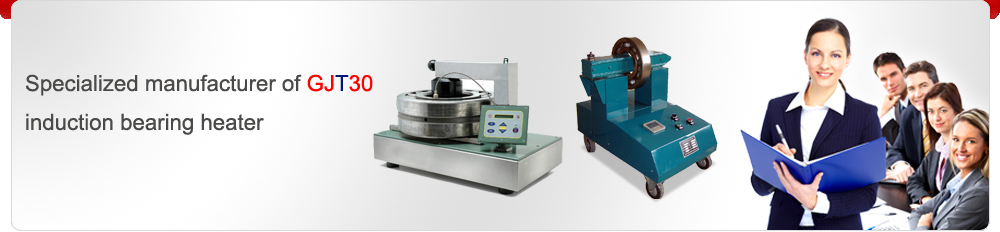

GJT30DIH Intelligent Bearing Heater( Desk-type )

Applicable to the quick heating of workpieces with thin wall, such as bearings and lantern rings and so on.

Function introduction of the control part:

* Temperature control

* Time control

* Automatic demagnetization

* Power adjustment

* To display the target temperature value of heating and the final actual temperature of heating

* To display the current heating temperature and left time of heating

* Warning tone for being over of heating

*Firm and reliable industrial design

* Heavy structure capable of enduring severe environment of the workshop

* Dust-proofing, water-proofing and oil resisting keyboards

*No damage to the bearing

* No impact on the lubrication of the bearing

* The shockproof base can prevent against any shock mark on the bearing caused by the environmental vibration during the heating

Easy operation

* The integrity control is visible.

* Design of convenient rotating heating rod or traveling car

Micro-electronics processor control

* Design for easy maintenance

* Self-diagnostic program

High efficient, energy-saving and environmentally-friendly product

* Quick heating, high efficient and energy saving

* Clean: no oil fume or oil vapor or wastes to be dealt with

* Safe, clean and environmentally-friendly

Traditional methods, such as flame, oil bath and eclectic furnace, are not only expensive, they produce fumes, terrible smell and waste oil as well. The induction heater replaces the traditional methods to create a safe and clean working environment.

* Quick, but no damage

After heating, the bearing will expand outward in the direction of cylinder, which can avoid the damage caused by assembly. The induction heating is a perfect heating mode which needs no pre-heating. It may take several seconds or several minutes to have the bearing heated to 120℃, which depends on the weight of the bearing. No damage will be caused to the advance lubrication.

* Rational design

To meet the requirements of the industrial environment, the design concept of GJT30 Series induction heaters is practicality, reliability, convenience and durability.

Operation procedures:

1. Switch on as required, and then the main engine will check the probe and the ambient temperature automatically and display the ambient temperature as well.

2. Press the function button to choose temperature control or time control. If it is necessary to adjust the temperature or the time, press the button of “up” or “down” to choose the proper parameter. When the temperature control is chosen, attach the magnetic probe to the outside of the bearing inner race. The highest temperature of the bearing can’t be over 120℃

3. Press the button of “start”. Then the main engine starts to heat the workpieces. When the set time of heating is over, the main engine will stop heating automatically and demagnetize. In the case of temperature control is adopted, the temperature of workpieces will remain constant when it comes to the set value. When assembling, press the button of “stop”.

4. The assembly can be implemented as soon as the workpieces are taken down

5:. When heating the same kind of workpieces, please use the time control method and please record the time needed for heating last time automatically.

Notes:

1. This bearing heater can check the probe automatically in the case of temperature control. So the heater can’t be started without a probe;

2. It is strictly prohibited to start the heater without installing the yoke;

3. It is advisable to use the well matched yoke when heating the workpieces in order to improve the work efficiency;

4. The highest temperature of the bearing can’t be over 120℃.

5. Please wear the heat resisting asbestos gloves when taking down the workpieces in order to prevent against burn.

6. Please do not leave the probe on the workpiece for a long time in case of shortening the service life of the probe.